Add to Cart

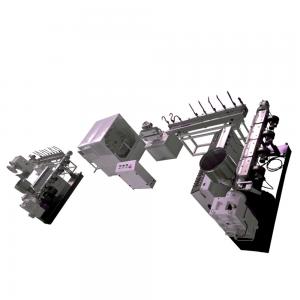

PVC fiber reinforced hose production line brief introduction:

| Model | PVC fiber reinforced hose |

| Pipe layers | Two layers PVC+ One layer fiber |

| Pipe Dia mm | 10-38mm |

| Output kg/h | 80-120 |

| Main extruder | HYSJ65/30-18.5kw *2 sets |

| Die head | Two sets die heads |

| Braider | Fibre Braider |

| Cool tank | Two Sets of cooling tank |

| Bake oven | One |

| Haul Off | 0.8-16m/min 1.5kw *2 sets |

| printer | Ink Shift Printer |

| Winder | 1.5kw motor manual |

Specification of the Machine:

| SN | Parts name | Specification | Description |

| 1 | Extruder | Extruder model | HYSJ-60/38 single screw |

| Output | 180kg/h for PE ,PPR pipe | ||

| Center height | 1000mm | ||

| Dimension | 3,100 x 1,400 x 2,300mm | ||

| Weight | 2400kg | ||

| 2 | Screw | Diameter | Ø60 mm |

| Screw ID ratio | 38:1 | ||

| Material | 38CrMoAlA + special alloy | ||

| Finish | Nitrogen-filled (0.50~0.70mm depth) and polish | ||

| Max rotate speed | 105 r/min | ||

| Core of the screw | Auto control for temperature |

| 3 | Barrel | Material | Bimetal barrel |

| Inside finish | Nitrogen-filled (0.50~0.70mm depth) | ||

| Heating control area | 5 areas | ||

| Heating way | Copper cooling fins with ceramic heater | ||

| Heating power | 15 kW | ||

| Cooling system | Low-noisy barrel cooling fan | ||

| Cooling power | 0.25kW x 5 sets | ||

| 4 | Gear box | Housing material | HT-500 |

| Gear material | 20CrMnTi | ||

| Gear surface | Hardened and ground in high precision | ||

| Axis material | 40Cr | ||

| 5 | Driving motor | AC motor power | 45 kW in Siemens brand |

| AC inverter controller | Famous Delta inverter in heavy type |

| 6 | Electrical Control system | PLC system | Whole Siemens PLC control system with HYPET soft ware. |

| Electric components | Branded in Siemens, Schneider RKC Omron, ABB, FUJI, and small unimportant parts in China famous brand | ||

| Extra temperature zone for die head | 7 zones | ||

| Electric cabinet feature | 1, electric cabinet can be disassembled with easy, 2, all cables and senses cables are strong enough with long life . 3, PLC monitor control system with button adjustment for controlling screw speed with easy . |

Afte -sales Service

| Items | quantity |

| Guarantee period | 1 year but he service is available lifelong, during guarantee period the cost of the components will be covered by the seller except the easy broken parts and damaged parts by the human reason |

| Training before shipping | Buyer’s technical person can be sent to china before shipping for training and operating, for 7-10 days |

| Technical documents | Electric principle drawing, operation manual, and electric parts manual etc |

| Seller engineers | Seller can send the engineers ot the buyer factory for commissioning and training. But the cost caused by the seller experts in the customer country will be covered by the buyer, including shuttle trip tickets inland traffic medical fee, lodging dinner and also 100 USD /day /one person as salary for the enigneers . |

| Contacts way | Whatsapp, wechat, mobile, etc +86 13823232106 |

| Company email : | info@hypet.com.cn |

Cooperative Brands:

Exhibition: